ÆMISSION is a specialized hardware which was developed to get the most from acoustic emission surveys. The software was designed with the help of professors from the Structural department of the Polytechnic University of Turin, who started to experiment with this technology more than 30 years ago.

Acoustic Emission (AE) is the phenomenon of radiation of acoustic (elastic) waves in solids as a result of damage or irreversible change to the internal structure of the material. Although the name itself suggests an audible signal, this is misleading, because the range of frequencies involved is between 50Khz and up to 1Mhz, practically ultrasonic frequencies.

Typically, the release of elastic energy and therefore AE occurs as result of cracks due to external forces (mechanical loading) or conditions (aging, temperatures).

Acoustic Emission is a very powerful method of surveying when applied to structural health monitoring.

The main applications of the AE technique are:

ÆMISSION is a unique acoustic emission data processor and recorder. What makes ÆMISSION different is the fact that it samples the analog data and elaborates it onboard, therefore providing the user with only meaningful data contrary to the products that are currently available on the market, which are data recorders that collect massive amount of data at high sampling rates and elaborate them in post-process on a pc.

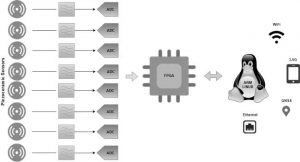

In the ÆMISSION analog signals, coming from the piezoceramic sensors are first electronically conditioned and level adapted by a cascade of analog filters before they can be converted into digital data. Eight high speed ADCs (1.25MSps@18bit or 5MSpsp@16bit), which are all synchronized to the same clock source, continuously convert the analog signal into digital.

In the ÆMISSION analog signals, coming from the piezoceramic sensors are first electronically conditioned and level adapted by a cascade of analog filters before they can be converted into digital data. Eight high speed ADCs (1.25MSps@18bit or 5MSpsp@16bit), which are all synchronized to the same clock source, continuously convert the analog signal into digital.

Digital signals are then parallelly acquired and processed by the FPGA and, according to the defined parametrization, only the events that satisfy the setting parameters are transferred to the Linux CPU.

Inside the Linux CPU events are stored locally and can be shared remotely via WiFi or a 4G connection.

The integrated GNSS receiver can synchronize multiple ÆMISSION units, and a virtually limitless number of acoustic sensors can be acquired.

ÆMISSION is supplied with 8 piezoceramic sensors, the sensing elements were selected and characterized with the help of the Polytechnic University of Turin so as to fulfil the needs of civil structure monitoring and to get the most accurate signals.

Typically, sensors are placed around the area that is to be monitored and connected to the ÆMISSION via 10m cables. Longer cables are available with active piezoceramic sensors.

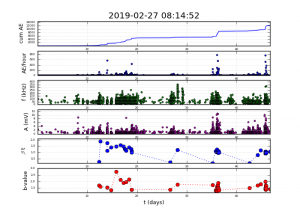

After a reasonable period of monitoring, the plots of the parameters are available and are useful to understand the nature of the cracking pattern and to provide an analysis of the monitored structure.

After a reasonable period of monitoring, the plots of the parameters are available and are useful to understand the nature of the cracking pattern and to provide an analysis of the monitored structure.

The following graph represents an ongoing survey in a marble quarry.

The following are displayed in order:

– AE cumulative count

– AE/hour

– Frequency of events

– Amplitude of events

– βt

– b-value

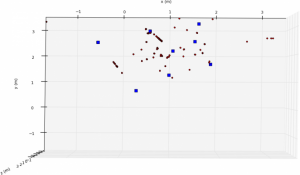

– A 3D graph of the emission sources is represented in the below graph.

Blue squares are the AE sensors, red dots represent the localization of the sources of emissions.

Blue squares are the AE sensors, red dots represent the localization of the sources of emissions.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_168680146_1 | 1 minute | Set by Google to distinguish users. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| Cookie | Duration | Description |

|---|---|---|

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| Cookie | Duration | Description |

|---|---|---|

| ack_1883718 | 1 day | No description |

| cf7emc_user_token | 1 day | No description available. |

| nv_1883718 | 77 years 10 months 21 days 15 hours | No description |

| prev2_1883718 | past | No description |

| pum-1781 | 1 day | No description |

| sid_1883718 | 30 minutes | No description |

| tll_1883718 | 77 years 10 months 21 days 15 hours | No description |

| vid_1883718 | 77 years 10 months 21 days 15 hours | No description |

| __wpdm_client | session | No description |